Color Case Hardening

What is Color Case Hardening?

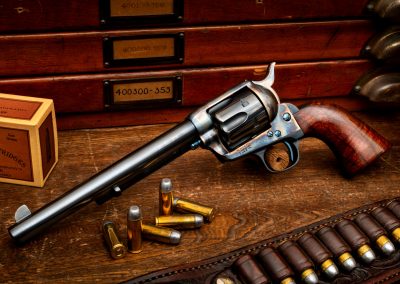

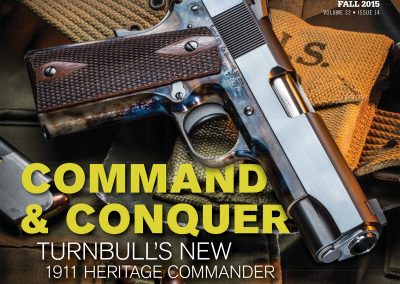

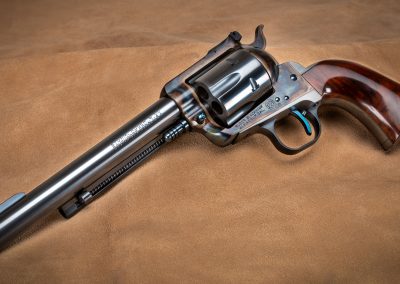

Color case hardening (sometimes referred to as case-hardening, case color hardening, or surface hardening) is a heat treating process and one of the earliest ways of hardening lower-grade steel. Originally, this process used bone charcoal heated to an exact temperature. Afterwards, the parts were removed from the furnace and quenched. The process leaves a hard surface finish and a layer of colored carbon with beautiful color variations. While the process is very controlled and the results are predictable, the exact color combination and pattern is unique to each firearm.

This process is different from the potassium cyanide salt bath process, utilized by manufacturers in later times. This treatment produces different colors and patterns than the original, period-correct, bone color case hardening. Turnbull Restoration perfected its use of this original bone charcoal process decades ago, and is known throughout the world for its work in this area of gun restoration.

Acknowledgement: Parts of this article are adapted from “Antique Metal Finishes” by S.P. Fjestad and Doug Turnbull, found in the 2nd Edition of the Blue Book of Antique American Firearms & Values. (link takes you to Midway USA)

Browse stories related to color case hardening on the Turnbull Restoration blog.

Color Case Hardening Gallery

Next Steps:

Are you a DIY-er?

Check out our Introduction to Metal Preparation video series.

What does it look like when it's all done?

Explore examples of color case hardening on restored antique and vintage firearms, and on factory-new firearms that we’ve refinished with our old-world methods.

Looking for more ideas?

Browse stories related to color case hardening on our blog, and subscribe to our newsletter to stay in touch.

Ready to start your project?

Contact us for additional information, or fill out our quote request form (restoration | refinishing) to get things rolling.