Turnbull Finished Services

A Service of The Finish Works by Turnbull Restoration View Our GallerySubscribe to Our NewsletterTransform Your New Firearms to Instant Family Heirlooms

Our antique gun restoration customers often ask us if their newly-manufactured firearms can be made to look like a 19th century classic. In many cases the answer is “yes”, and that’s why we now offer Turnbull Finished Services. Explore the possibilities and request a quote today.

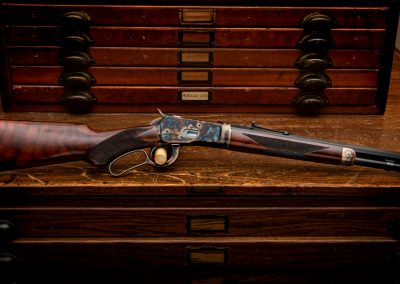

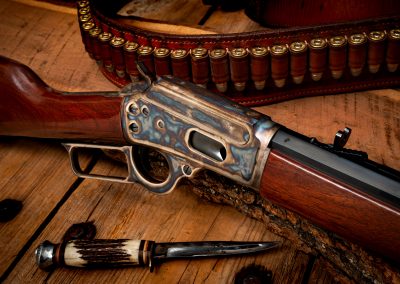

Our transformative methods are performed by the same craftsmen who are expert in the renewal of old-world legends. Finishes and techniques have been meticulously developed to match those of the original gun makers of yesteryear. Bone charcoal color case hardening, charcoal bluing, rust bluing, nitre bluing, hand-rubbed oil wood finishes, engraving – all period-correct and worthy of heirloom status.

(Shown in Video: Factory-new Winchester 1892 Carbine with 19th-century finishes and tang safety conversion. Watch the full video here.)

Frequently Asked Questions

What sort of finishes do you offer?

The metal and wood finishes we apply to factory-new firearms use the same old-school, classic-era methods and materials that we’ve perfected over the past 30+ years in our restoration services business. The specific finishes we use on your project depend on the firearm model and the part of the gun involved (see our list of factory-new models we work on, below).

Restoration-Grade Metal Finishes:

If you’re looking for that legit, 19th century look for your 21st century model, the Turnbull way is the period-correct way.

Restoration-Grade Wood Finishes:

- Hand-rubbed buttstock and forend finishes using our own in-house formulations. Nothing says classic like that unmistakable red shading.

Which gun models do you work on?

The list of factory-new firearms we work on is less extensive than the variety of classics we bring back to life in our main gun restoration business. We’re very selective on purpose, and are always assessing which models are the best candidates for old-school transformation.

Browning:

- BL-22 (color case hardening of carbon steel receiver)

- Buck Mark (color case hardening of carbon steel barrel)

CZ:

- 457 Lux (color case hardening of carbon steel receiver)

Marlin:

- 336C (color case hardening of receiver and other carbon steel parts, wood refinishing)

- 1894C (color case hardening of receiver and other carbon steel parts, wood refinishing)

- 1894CB (color case hardening of receiver and other carbon steel parts, wood refinishing)

- 1895 (color case hardening of receiver and other carbon steel parts, wood refinishing)

- 1895CB (color case hardening of receiver and other carbon steel parts, wood refinishing)

Ruger:

- LCP, LCP Max, LCP II, EC9s, LC9s (color case hardening of carbon steel slides)

NOTE: Ruger LCP, LCP Max, LCP II, EC9s, LC9s are the only eligible pistols in this category at this time; contact our customer service team with any questions - Single-action revolvers (color case hardening of carbon steel frames)

- GP100 (color case hardening of carbon steel frames)

- Mark III Target (color case hardening of carbon steel barrels)

- Mark IV: Target, Standard, and 22/45 (color case hardening of carbon steel barrels)

- No. 1 (color case hardening of receiver, rust blued barrel, charcoal blued small parts, nitre blued screws and pins – carbon steel parts only)

- Vaquero (color case hardening of carbon steel frames)

Uberti:

- Various revolver and rifle models (color case hardening of carbon steel frames and receivers)

Winchester:

- 1873 (color case hardening of receiver and other carbon steel parts, rust blue barrels, charcoal blue small parts, wood refinishing)

- 1885 (color case hardening of receiver and other carbon steel parts, rust blue barrels, charcoal blue small parts, wood refinishing)

- 1886 (tang safety conversions, color case hardening of receiver, rust blue barrels, charcoal blue small parts wood refinishing)

- 1892 (tang safety conversions, color case hardening of receiver, rust blue barrels, charcoal blue small parts , wood refinishing)

- Model 94 (color case hardening of receiver and other carbon steel parts, rust blue barrels, charcoal blue small parts, wood refinishing) *Please note, we cannot do any refinish work on Model 94s manufactured from 1964-1984, due to the composition of the steel.

I don’t see my gun on your list for refinishing services. Can you still work on it?

There are some models that we’ve identified aren’t good candidates for color case hardening. These may be too delicate to withstand the temperature of the oven, have a very specific hardness, or have a unique steel composition that doesn’t yield good results. Here are some models we don’t offer color case hardening on:

- Smith & Wesson revolvers

- Pistol slides (Exception: Ruger LCP, LCP II, LCP Max, LC9s, EC9s)

- Double action revolvers (Exception: Ruger GP100)

- Desert Eagle pistols

- Winchester model 70 rifles

- Winchester 94 rifles manufactured 1964-1984

There are other models that we will color case harden but aren’t offering disassembly, polishing, and reassembly on, so you would need to have another gunsmith prep the parts before sending them on to us. In general, these will be:

- Over/under shotguns

- Bolt-action rifles

We’re happy to talk about your specific project and explore the possibilities. Please contact us so we can learn more about your firearm. And if we can work on it, we’re happy to supply pricing and turnaround time to transform your factory-new firearm into a Turnbull classic.

What kind of metal can be refinished?

If it’s carbon steel of a certain grade, chances are we can refinish it. If it comes from the factory already blued, that’s a good sign. However, it’s always best to contact us first to be sure.

Stainless steel, aluminum, and some coated carbon steel (not blued) cannot be refinished. Sorry!

Can you engrave my new gun?

You betcha! Our in-house engraver Tom McArdle – the man responsible for our unparalleled restorative engraving – is an artist in the truest sense, and has adorned factory-new pieces with his work as well.

We encourage you to browse the galleries in our Engraving Services page or contact us to explore the possibilities.

How do I ship my gun to you?

We’re glad you asked, and have created a helpful page dedicated to firearm shipping information.

Can I prepare my gun’s metal myself before sending it to you for refinishing?

You sure can! And doing so could end up saving you some time and money. It’s best to contact us so we can share the specifics with you **. In the meantime, our Introduction to Metal Preparation video series will provide you with a helpful overview.

** PLEASE BE ADVISED: sometimes we have to quote additional polish work or decline a project if we feel the finish on a piece we receive for work isn’t up to our specified standards. Basically, if the prep and polish isn’t right, the finishes won’t be right. So just keep that in mind if you plan on doing your own metal prep and polish.

I don’t have a new gun for you to refinish, but I’d love to have a Turnbull in my collection. Do you sell rifles and handguns that you’ve already refinished?

Yes! The sort of transformation we’re talking about here isn’t limited to customer-supplied guns. Browse our full range of Turnbull Finished favorites and select your instant classic from our showroom of factory-new models that have been put through the Turnbull time machine.

Looking for a pre-owned gun that’s either been restored or refinished by us for the previous owner? We have those in our showroom as well.

What’s the difference between restoration and refinishing?

Our core business in firearm restoration – decades in the making – is in bringing classics of yesteryear back to their original factory condition.

In a nutshell: If you have an antique heirloom that is also a model we specialize in, it’s a candidate for restoration. If it’s a factory-new model that you want to look like an antique, it’s a candidate for refinishing.

Request a Quote

Before sending in your firearm for restoration, please print and fill out the REQUIRED Restoration Request Form and mail it in with your gun. This step is REQUIRED even if you’ve already spoken to us as it helps ensure timely, accurate response once your firearm is received. Quoting usually takes about six weeks. We will contact you, via mail, when we receive your firearm. If you have questions regarding shipping your firearm, refer to our Shipping Information page.

For further questions, please fill out the contact form below or call us at 585-657-6338.

Thank you!

WORK REQUEST FORM